Ceramic Machinery

Complete lines for SANITARYWARE production

Ceramic Machinery

Complete lines for TABLEWARE production

Ceramic Machinery

COMPLETE MACHINES AND SYSTEMS FOR PRODUCING CERAMIC TILES AND SLABS

CERAMICS, BETTER

The CERAMICS Division of FEBEX designs, manufactures and supplies machinery and complete systems for producing tiles, sanitaryware, tableware, refractories, special ceramics and technical items.

The high technological quality of its supplies is the hallmark of FEBEX - whose role as the leading technological partner for the ceramic industry is widely acknowledged.

The use of the most advanced technologies allows for progressive replacement of manual processes with automated production processes, not only in traditionally more advanced markets but throughout the global scene.

In particular, in recent years, considerable efforts have been devoted to extending Industry 4.0 methods and processes to all the ceramic production cycle phases.

Within this scope, FEBEX knows how to make the most out of the investment efforts of its long-standing customers and of the interest aroused among top international groups.

CERAMICS, BETTER

Technological innovation and automation make the machines and FEBEX tile production systems extremely competitive in terms of efficiency, costs, production quality, energy savings and easy switching from one production batch to another in shorter times. Production and automation aspects are developed harmoniously to allow for a reasonable initial investment ensuring any required future expansion of automation levels.

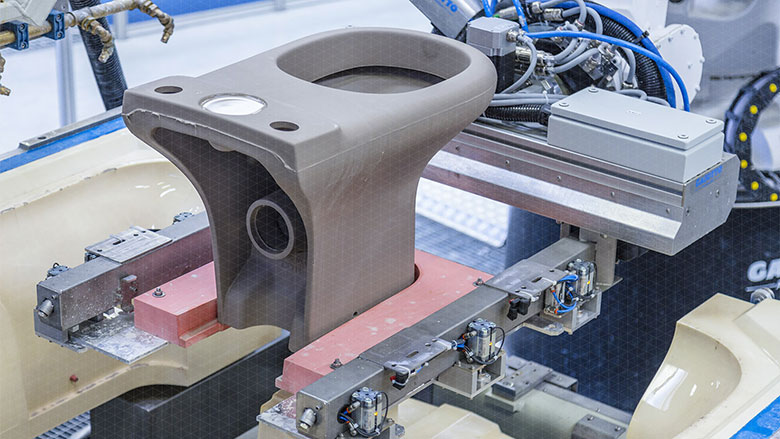

SANITARYWARE

The FEBEX Sanitaryware division, thanks also to the technological contribution of the Riedhammer and Gaiotto group companies, is able to develop turnkey production systems with a very high level of automation. Thanks to in-house expertise and process know-how, FEBEX plants ensure top production flexibility, low manpower requirements, focus on operator safety, and reduced consumption. FEBEX solutions are able to integrate all the processes necessary for turning an idea, a sketch, a design into a finished product that can be produced cost-effectively on an industrial scale.

TABLEWARE

FEBEX WhiteWare supplies turnkey systems for the production of ceramic tableware. Every FEBEX WhiteWare company is specialised in a particular production phase, from body and glaze preparation to moulding, glazing, polishing and decoration. By working in synergy, they create a complete chain that involves the entire production cycle, ensuring optimal installation of complete production lines and flexible solutions for process innovation. FEBEX provides the common thread linking all the phases of this production process: the organisational, technological and commercial connection among the plants, machines and technologies necessary to produce ceramic tableware by guaranteeing high quality in every phase.

ADVANCED TECHNICAL CERAMICS

Drying, tempering, pre-sintering and sintering are the thermal processes necessary for the production of technical ceramics. Riedhammer offers its customers the best solutions to achieve excellent results together. Riedhammer responds to every request by offering high-performance systems for intermittent or continuous production.

FEBEX offers advanced levels of synergism in the production process of technical ceramics, and offers added value to its customers in the form of latest-generation technology and extremely rigorous quality control at every stage.

The applied set of FEBEX skills allows specific customer needs to be met, offering a range of the best cutting-edge solutions available today, both technically and financially.

REFRACTORIES

Since more than 100 years Sacmi Group is the leading supplier of equipment and service for the Refractory Industry.

A wide range of products that fits even the most demanding needs: flexible, efficient, precise and powerful machines help our Customers worldwide in getting the most out of their production lines.